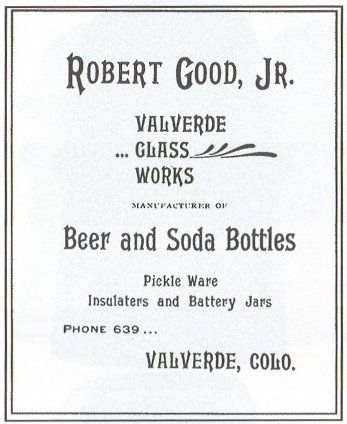

Robert Good, Jr. & His Insulators

Reprinted from "Crown Jewels of the Wire", February 2005, page 27

Born in England in 1866, immigrant Robert Good, Jr arguably influenced

insulator production in the American West more than any other single individual

in his generation.

Learning the glass trade from his father, Robert Junior arrived in Denver,

Colorado area in 1895 to take over a glass plant that had gone out of

production. The factory, actually located in the nearby community of Valverde,

primarily produced bottles.

In an article in a Denver newspaper in 1896, Good is quoted as stating,

"Orders are now in for about 100,000 soda bottles, beer bottles and pickle

goods also form a large part of our output. This fall we expect to supply the

bulk of the fruit jars used in Colorado and ultimately in the entire

West."¹

The manufacture of insulators was mentioned in a May, 1897 magazine article

which stated, "Among the articles manufactured are pickle bottles, olive

oil bottles, half-gallon water ,bottles, catsup bottles, green packing bottles

for druggist's use, and also pop bottles and insulators. The insulators are all

handled by the Rocky Mountain Electric Company. Twenty men and boys receive

constant employment. The ware is equal to the best manufactured in the East."²

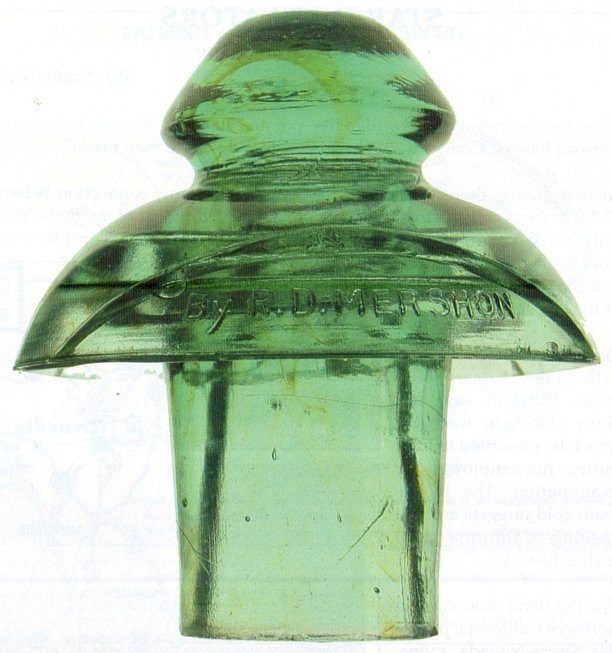

Good produced insulators in four different CD styles that were embossed with

his name. A fifth insulator attributed to Good's factory was the CD 288 Mershon

(see page 32).

Among the many Denver area teenagers hired by Good to work in the plant was

a young man named William McLaughlin. It was in Valverde that McLaughlin began

to dream of owning his own glass plant, culminating in the production during the

1920's and 1930's of insulators embossed with the McLaughlin name. McLaughlin

would describe Robert Good in the following words, "Bob Good was well liked

by everyone in Valverde. He was an active church member and was good to the

kids. He would stop by our house on Wednesday evening and he and my father would

go to prayer meeting together where he really enjoyed the singing."³

Good's Goods

|

|

The smallest insulator made by Robert Good was the CD 106 pony. These are

reported only in aqua. The example on the left sports a large bubble in the

dome; while the example on the right is filled with milky swirls. |

|

CD 134 insulators embossed "Good" are also generally found in aqua

colorations, with sage and light green varieties also known. The insulator to

the left, with heavy amber swirling, is an exceptional specimen of a 134.

CD 121 tolls, as evidenced on the page opposite, are found in a dramatic

array of colors. Royal purple R. Good's are tough enough to find, but the two

tone purples, and the bright green examples, would be "top shelf"

items in most any collection.

Robert Good apparently used three molds in the manufacture of each style of

insulator. The tolls, particularly, are found with one, two or three dots below

the embossing to identify different molds.

|

|

May 1897 ad from Industrial Reporter

In his recollections, McLaughlin made the following comments about Robert

Good's operation:

"The Valverde factory had a pot furnace with a tall brick chimney eighty

feet high. Mr. Good had to make some changes in order to build a tank furnace.

He had to remove the big clay pots that were under the chimney in order to

install the tank. Coal was used to heat and melt the glass and there was a pit

under the furnace into which the ashes dropped. A big wagon pulled by two horses

was used to remove the ashes from the pit. To keep the fire extremely hot, the

fire box door was kept open. An experienced

man called a teaser would squat down on the coal pile and toss pieces of coal on

spots in the fire box as soon as they began to look dark, thus keeping the fire and the temperature

even."4

Mining for gold, silver and other ores still dominated the economy of

Colorado and much of the American West at the end of the 1800's. Telephone and

electrical power lines were rapidly expanded across the landscape. The demand

for insulators was great. But there was no other major manufacture of insulators

in the West during the period. EC&M and Cal. Elec Works production ended in

the 1880's, and the California Glass Insulator Company didn't begin production

until 1912. Insulators manufactured by Robert Good's company, and its

successors, successfully competed against Hemingray and Brookfield, who's

products had to be transported over much greater distances.

Insulators produced in Denver were found in use, not only in Colorado and

New Mexico as one would expect, but on railroad lines in Arizona, telephone

lines in the mountains of Northwest California, and as far away at the Postal

Telegraph Line in Oregon.

Regarding colors, even before Good took over the factory, its predecessor was

called the Denver Flint Glass Company. The manufacture of clear (flint) glass

was well established prior to making insulators. Clear glass was the result of

adding manganese to the glass batch. But manganese reacted to the ultraviolet

rays of the sun to turn the glass purple over time. The more manganese was used,

the darker purple bottles and insulators would turn under solar radiation.

Insulators used indoors and never exposed to the sun could remain off clear.

Green colored insulators may have resulted from using glass originally intended

for druggists bottles. However, amber swirling from other impurities in the

glass can turn an otherwise aqua insulator into a one with green tones (see the

example of the Mershon on page 33).

Robert Good's factory was destroyed by fire in June of 1899. Reportedly a

glass furnace burst, and the molten glass set the building on fire. The cost of

rebuilding the factory was too much for Good. He stayed around to oversee the

reconstruction of the plant. But it opened in October of 1899 under new owners

who operated under the name, Western Flint Glass Company. By the end of 1899, Good was living in New York.5 He continued a career in the glass

business until he was in the eighties.

Insulators embossed W.F.G. Co. were only produced for about one year before

the company was re-organized under the name, Western Glass Manufacturing

Company. Insulator embossed W.G.M. were produced until mid-1909. Crown Jewels

will print articles on insulators embossed with each of these names in future

issues.

References:

1. Insulators: A History and Guide to North American Glass Pintype

Insulators, by John & Carol McDougald, 1990, page 96.

2. Insulators: A History and Guide to North American Glass Pintype

Insulators, by John & Carol McDougald, 1990, page 96.

3. Dreams of Glass: The Story of William McLaughlin and His Glass Company, by

Fred Padgett, 1996, page 13.

4. Dreams of Glass: The Story of William McLaughlin and His Glass Company, by

Fred Padgett, page 13.

5. Insulators: A History and Guide to North American Glass Pin type

Insulators, by John & Carol McDougald, 1990, page 97.

6. Dreams of Glass: The Story of William McLaughlin and His Glass Company, by

Fred Padgett, page 11.

Photograph of Robert Good, Jr reprinted from McDougald's book, page 100.

Advertisement reprinted from McDougald's book, page 97.

Color photographs of insulators taken by Howard Banks.

Crown Jewels thanks

Mike Miller for allowing us to photograph his insulators for this article.

Color

printing is provided by Tommy Bolack.

CD 162 R. Good, Jr signals, often used for low voltage power, are found in

several colors. Among the most desirable are sage green, off clear, and dark

purple. Manufacturing flaws add character to any insulator, and the crooked,

sleepy-looking dome on the one in the upper right corner is a prime example.

Coming up in 2005, Crown Jewels will run feature articles on insulators

manufactured by the successors to R. Good, Jr: Western Flint Glass and Western

Glass Manufacturing. In one of those articles we'll report on the unembossed two

piece transpositions made in the Denver glass houses.

Many collectors believe that CD 288 power insulators embossed with the name

of their inventor, R.D. Mershon, were manufactured by Robert Good, Jr at his

glass plant outside Denver. Mershon is reported to have been an employee there

at one period. So was a teenager, William McLaughlin, the future manufacturer of

McLaughlin insulators. McLaughlin later recollected, "Things were going

fine with regular insulator production until we received an order for a special

high power insulator. The boy who was sliding the glass filled mold into the

"V" shaped stop where I would remove the screw plug which made the

threads, was sliding it too hard and all the top portions of the insulators were

coming out checked. I was being blamed for these failures, and it was some time before I figured out what was

wrong."6

After a week, McLaughlin traded jobs

with the other boy. He was more careful about forming the top, and the

insulators came out successfully. The CD 288 example shown above has significant

amber swirling which gives the insulator an overall green appearance instead of

the normal aqua. Also note how tall the base is. The height of Mershons varied

by how much glass was put into the mold. For more on Mershons, see the inside of

the back cover.

|